When plastic breaks

My colleague has bought a new horse trailer. After a few weeks, she discovered a crack in the polyester trailer roof. It looked as if someone had bumped into the trailer – unfortunately, no one came forward who caused or witnessed the accident. A very annoying incident! The damage had to be fixed as quickly as possible, so no moisture would penetrate the material and the crack would not spread during the next trip.

The right adhesive for the polyester roof

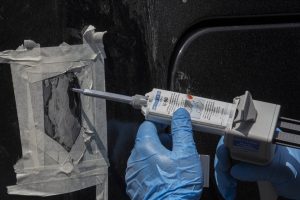

So we discussed how to fix the damage as quickly, easily and cost-efficiently as possible and decided to use our Easy-Mix PU-90 Polyurethane Adhesive to repair the roof. PU-90 bonds many materials such as fiber composites, plastics, polyurethane, epoxy, polyester, metals, wood and ceramic with high tensile, shear and peel strength to and among each other. The adhesive is used in metal construction, in boat and shipbuilding or in car body and vehicle construction. Therefore, the PU-90 Adhesive is well-suited for our repair work – even more so because of its black colour and short cure time.

How it’s done:

First, sand down the crack using a Dremel tool, so the plastic is roughened and can absorb the adhesive better. Clean the crack with Surface Cleaner after sanding. The cleaner evaporates without leaving residues.

In order to get straight edges, we recommend to mask the part you want to repair. Then apply the PU-90. To prevent bubbles and get an even surface, we put a PE foil over the part where we applied the adhesive and thus smoothened the polyurethane. As a result, after removing the PE foil, we had an even and sealed surface, which prevents moisture penetration.

The structural adhesive is overpaintable after approx. 30 minutes. Keep that in mind in case you want to correct the ‘beauty flaw‘ by painting over it.