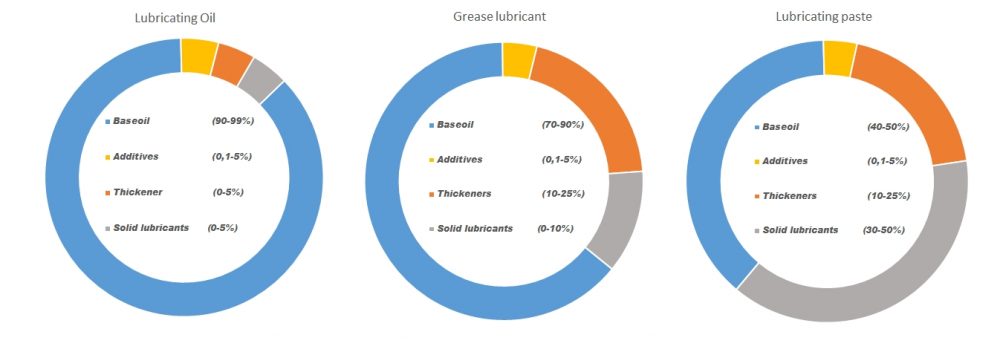

The composition of lubricants

Modern lubricants consist of a number of different components. In most lubricants, the base oil is the most important part of the composition. Further components are thickening agents, dry lubricants and additives. By selecting the ingredients carefully, lubricants with different characteristics can be produced.

The base oil

The base oil gives the lubricant its essential characteristics and can be made from different products. Often, highly refined mineral oils are used, which are characterized by their well-rounded performance profile, excellent quality and high availability. Today, synthetic base oils like polyalphaolefins, ester oils or polyglycols are used for many modern lubricants. These oils show higher thermal stability and are more resistant to oxidation and chemicals. Moreover, most of these lubricants do not affect modern materials like plastics, composites or gasket materials.

Thickening agent

A thickening agent causes an increase of viscosity. That way, a lubricating oil, for example, can be thickened until it has a gelatinous consistency. Therefore, thickening agents are sometimes referred to as consistency enhancers. Thus, with the help of thickening agents, a lubricating grease can be made from a base oil. In the process, it is possible to adjust the consistency as required – from smooth fluid greases to rigid block greases – and, that way, to produce products for various application areas. Moreover, thickening agents can have a positive effect on the qualities of the lubricants, for example, they can improve the lubricant’s resistance to water or chemicals significantly.

Solid lubricants

Solid lubricants like PTFE, MoS2, graphite or similar materials can be added to lubricants in order to develop products for special fields of application or in order to optimize already existing lubricants. Solid lubricants reduce friction due to their composition and, moreover, they can also give a product corrosion protection properties. They are often used in lubricating greases or pastes, as they blend in better with their compositions than in lubricating oils. Solid lubricants also increase the pressure resistance of a lubricant and are therefore used in WEICON assembly pastes, among others.

Additives

In order to generate special qualities in a product, additives are used in its composition. They can either promote or inhibit certain characteristics. That way, a number of improvements in terms of temperature or pressure resistance, water repellency, wetting ability, oxidation stability or corrosion protection properties can be achieved. Thanks to the careful selection and combination of different additives, WEICON lubricants show excellent quality and performance.

Multifunctional oils and multi-purpose greases

Lubricants are usually tailored to a certain field of application, yet they are often suitable for different applications as well. So-called multifunctional oils or multi-purpose greases offer its user a large application range and high flexibility. In general, the composition depends on its areas of use, as the requirements it as to fulfill in subsequent applications determine the selection of its ingredients.

Dry film lubricant coatings

Dry film lubricant coatings are so-called dry lubricants, which combine a binder and solid lubricants like MoS2 or PTFE. They are mixed with a solvent, which evaporates after its application and leaves a dry film lubricant coating on the surface. Dry film lubricant coatings can be applied to a surface like common coatings by dipping, painting or spraying. The dry film lubricant coating is between 10 und 20 µm thick and able to resist stresses due to high temperature or pressure. In addition, the coating does not absorb dust and has a high durability and resistance to chemicals.

Advantages dry film lubricating coatings:

- permanent dry lubrication without oil or grease

- effective lubrication even after longer downtimes

- extreme pressure resistance

- resistant to dust, soilings, moisture and most chemical influences

- high temperature resistance in large temperature range

- no evaporation loss and excellent bond strength

- vacuum usage possible

- enable dry-running properties

- long-term corrosion protection

- replacement of environmentally harmful coatings

Mixing lubricants

As the mixing of lubricants often has a negative effect on the product qualities, we always recommend only to apply ready-to-use lubricants and to not change their compositions yourself. When replacing one lubricant in a lubricating system with another one, the old lubricant should be removed completely from the system, either by rinsing or by driving out the old with the new lubricant. However, the general compatibility of both lubricants should always be tested beforehand. This also applies when several lubricants are used in one machine where they could possibly mix.

How to find the right lubricant you get to know here.